History of Aoyama Optical / A consideration of FACTORY900 Store staff

When I visited the headquarter of Aoyama Optical in Fukui prefecture, our designer Yoshinori Aoyama told various stories to me: History of Aoyama Optical, History of FACTORY900, the things he valued, Future, …

On that day, I was allowed to access to the heartbeat of factory which is our top secret, and I saw our secret production process with my own eyes.

I was impressed by its technology, but I was not surprised since I have already understood that FACTORY900 collections must be full of special technologies with special equipment.

However, I came to change my initial impression completely when I experienced the final polish procedure by myself.

Of course, the most part of production to form eyeglasses is processed using machinery. What I was surprised was that there were many final processes realized only by hands. Fine formation, many phases of polish…

In addition, the final quality control is under the eyes of proficient artisan who sets high quality standard. He stacks many rejected eyeglasses which didn’t pass his severe standard. I remember I was shocked as the number of eyeglasses which come up to the standard was smaller than the number of rejected eyeglasses.

I realized I had seen only a part of futuristic design of FACTORY900 until that day. But I finally understood that FACTORY900 collections can be realized only with great time and effort. And I was impressed also by our artisans who took their brilliant work as a matter of course.

Then, I wanted to learn more about our history, and the history of Sabae-Fukui region as the production region of eyewear glasses.

Eyewear glasses country – Sabae, Fukui

Sabae is a well-known city for its production of optical frames in Japan. It’s situated in the center of Fukui prefecture with a population of 70,000 people.

Sabae is famous not only for the production of optical frames (95% of Made in Japan eyeglasses are made in Sabae-Fukui region), but also for the production of ECHIZEN lacquer ware and textile. Craftsmanship is one of the most essential things for us from the beginning of our history.

Everyone thinks that SABAE glasses are made only in Sabae city as a common sense. But it’s not true: Many optical companies and factories are situated in both Sabae and Fukui cities. In fact, our headquarter is situated in the south part of Fukui city. So properly speaking, 95% of Made in Japan eyeglasses are made in this Sabae-Fukui region. And today, through 100 years of history with eyeglasses developing high technology and quality, this Sabae-Fukui region is one of the three largest production regions for optical frames in the world, alongside Italy and China.

Aoyama Optical

| Factory |

During the previous generation, Aoyama Optical was the factory specialized in OEM production. Everyone called us “last resort”, and the particular requests which the other factories had rejected to realize have been always brought to us, since we have never said “Impossible to produce”. We have always tried to find the solution before giving-up. We have always valued the challenger’s spirit and ambition which have enabled us to realize also the unreasonable demands.

Our stance is always same from the beginning. Our history of over 80 years and accumulated know-how enable us to realize FACTORY900 collections of today.

The mechanical technology cannot be driven by everyone. Nobody can become an artisan in a day. Our technology is always maintained and improved everyday by the small number but exceptional talented artisans.

| History |

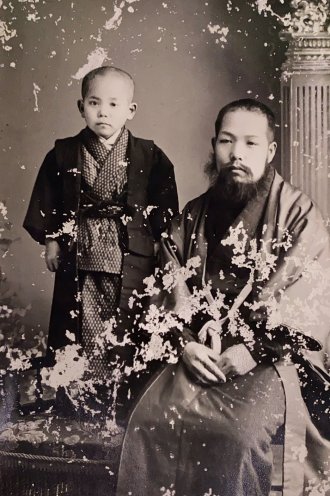

Our history had begun in 1905, when Hikozaemon AOYAMA (1879-1961), Great-Grandfather of actual president, called several artisans from Tokyo to Fukui and started to manufacturer the glasses there. Hikozaemon, however, was the vice-postmaster at the same time. He worked as a postman and meanwhile as an artisan and maestro of eyeglasses to guide his disciples in their training.

One day in 1908, he had had to take over the position of postmaster, and he had decided to take over his disciples and all his tools to his cousin Gozaemon MASUNAGA and his factory of eyeglasses had been closed.

Afterwards, Katsuhiko AOYAMA (1905-1994), second son of Hikozaemon became a disciple of Masunaga Optical in 1920 since he aimed to revive the manufacture of optical frames which his father had begun. And in 1937, he struck out on his own, and founded FUKUI KYODO GLASSES Manufacturing (the predecessor of AOYAMA Optical) in Fukui city. And in 1969, AOYAMA Optial was finally founded.

Over 80 years of history since Katsuhiko AOYAMA had founded his own company.

Over 110 years of history since Hikozaemon AOYAMA had started to manufacture the eyeglasses.

The whole history of AOYAMA overlaps with the whole history of eyewear industry in Fukui.

| Production System |

Currently there are around 500 Optical companies in Sabae-Fukui region. And the production process of eyeglasses in this region is generally divided into several phases. Many companies are forced to bring their plan and design to other companies for the eyeglasses production.

The production companies themselves had been stressed to increase productivity. Accordingly, this circumstance accelerated the division of production process for each company.

On the other hand, we, AOYAMA Optical manage not only the whole planning and design, but also over 90% of production of eyeglasses within our own factory, thanks to our high technology through our long history. In 2015, we opened our flagship store in Tokyo. Finally, we manage the whole process from the beginning of design to the retail sales.

We have full knowledge of pros and cons of our products as we proceed with (almost) whole production process by ourselves. This enables us to offer careful after sales service to our customers. We believe that the eyeglasses are not throwaway products, but the products which can be matured with people who use them. We are responsible to support the customers’ eyewear life. One of our strengths is built by this construction of our company.

| Production method |

Our production method is a trade secret. No one can access to the heart of our factory.

There are mainly two production methods of plastic eyeglasses: One is to curve and cut the acetate plate. And another is called “Injection method” which is to inject, and shape melted resin chips in mold.

The injection method is very easy for mass production once the mold is ready, and very flexible for any kinds of designs. While the first method requires many manual works, therefore it can be inferior in productive capacity. For such reason, the most part of plastic products are produced using Injection method. Regarding the production of eyeglasses, generally speaking, the sports sunglasses and low-cost eyeglasses are produced using this injection method.

On the other hand, you can see a lot of flexibility in the designs of FACTORY900 collections and the eyeglasses made in AOYAMA Optical factory. Therefore, many people thinks that our products are made using Injection method. However, to tell the truth, all our products are cut and curved from an acetate plate. And our production method is the one and only in the world. Even the professionals of eyeglasses manufacturing industry cannot imagine how our eyeglasses are produced.

| Bloodline / Protagonists who bear the history |

We would like to introduce our innovators who always made / make new ways among the eyeglass’s history in Fukui…

Hikozaemon AOYAMA (1871-1961)

Great Grandfather of current president. One of meritorious persons who had established the base of eyeglasses country in Sabae, Fukui.

In fact, mother of Gozaemon MASUNAGA (Founder of Masunaga) was born in Aoyama family, therefore they were cousins.

Katsuhiko AOYAMA (1905-1994)

Grandfather of current president. The founder of AOYAMA Optical and the first engineer who had begun his research and development of celluloid eyeglasses in Sabae. After his graduation from senior elementary school, he had become a disciple at Masunaga Optical. He had markedly stood out there, he had produced the technology and the tools for eyeglasses manufacturing. Meanwhile he had continued to research and develop the celluloid eyeglasses. He stood on his own feet in 1937, and he had founded his own company specialized in the production of celluloid frames.

Kyoya AOYAMA (1939-)

Current chairman of AOYAMA Optical, and father of current president. A pioneer who brought the numerically-controlled machine to the eyeglasses production. He cooperated with TOSHIBA in 1970 to develop and introduce the special numerically-controlled machine only for eyeglasses production. He never stops with system construction of machine as the machine efficiency improves day by day. And he came to establish our own three-dimensional modeling technology using the present five-axis machining center. He always has new ideas up his sleeves regarding the plastic eyeglasses production and he is still an active engineer.

Takashi AOYAMA (1969-)

President at AOYAMA Optical, and a system engineer who undertakes responsibility of development and planning of systems. He was always besides his father from his school days, and involved in system construction together, in particular for the software development. From the custom-made system which can make the eyeglasses to match individual face lines, until the construction of our own CAM system which is one of the most important technology at AOYAMA Optical, he plays various roles.

Yoshinori AOYAMA (1972-)

Senior Executive Director at AOYAMA Optical. Brother of President. Artisan, and meanwhile, designer of FACTORY900. The person who adopted the innovation called “DESIGN”, on the basis of brilliant technical skills, to the company full of history, tradition, technologies and craftsmanship. He demonstrated to forge AOYAMA Optical’s own path in the world winning various international awards with his collections.

About FACTORY900

| Origin of a name |

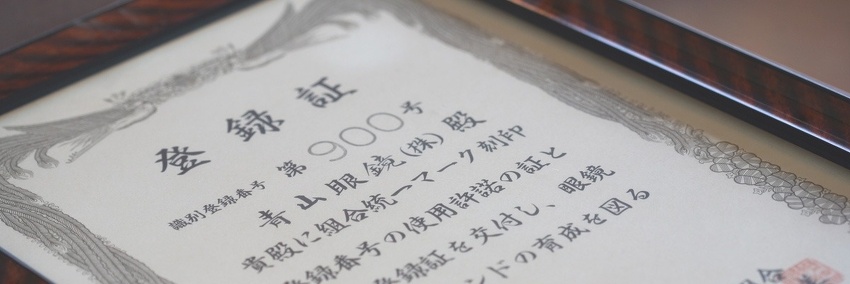

As the name “SABAE GLASSES” were getting famous in the market, several problems of fraudulent production origin occurred. In 1994, Fukui Optical Industrial Association gave the registered identification number to each factory in order to define the correct production origin. 900 is the number which was gave to AOYAMA Optical. And the same number became a part of brand name.

| Brand history and our future |

FACTORY900 is a brand which was born to express freely what we wanted to create on the basis of our high technology developed through our long history and experiences.

The brand was launched in 2000. At the beginning, the brand was launched just for the ideas and examples of OEM production. However, Yoshinori AOYAMA aimed to reincarnate the company from OEM Company to the producer of our own brand with value. In 2001, he launched his collections and started to present it at IOFT as our own brand.

He cherishes “product itself” when he designs FACTORY900 collections. And the core of his philosophy is his question “if people can cry only by seeing the eyeglasses” and his wishes “to create something beautiful” and “to create something which can touch people’s heart”.

However, he knows that the “beauty” is not something which dwells inside the product. But what people feels beautiful may depend on the people who sees. To feel “beautiful” means to be “touched”. As we wish that many people feel “beautiful” with our eyeglasses, we are responsible to create many eyeglasses which can touch more people.

If we focus on touching the people, the new things and the unknown things can touch the people in the sense of “surprise”. Replacing the new “things” with “future”, we always raise the word “THE FUTURES EYEWEAR” as our concept. We continue to pursue the “newness”, aiming to touch the world.